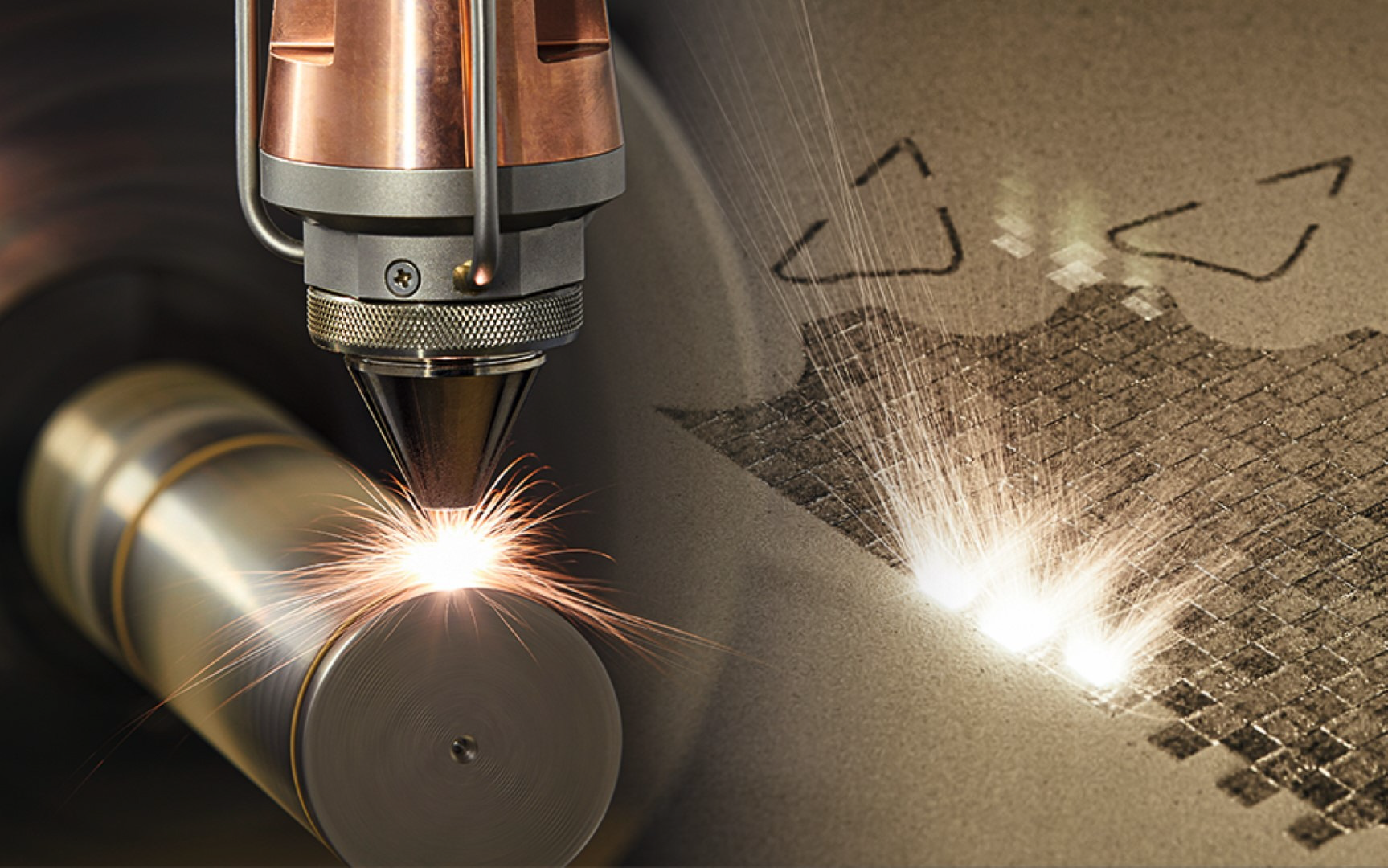

The removal of support structures has traditionally been a time-consuming and physically demanding process for metallic 3D-printed parts. Conventional methods, such as using hammers and chisels, not only place a physical strain on employees but also increase the risk of damaging the components. The dry ice blasting system offers an efficient solution by partially automating the process and improving ergonomic working conditions. This reduces bottlenecks and the risk of part damage while increasing overall productivity. Depending on specific requirements, the cycle time per component can be reduced by up to 80%. The SupportBlaster 320-HA features an intuitive user interface and versatile clamping options. Additionally, the teach-in function provides a straightforward automation option, which can be further enhanced through optional robotic integration.

More products of AMbitious powered by toolcraft

Contacts

Contact

AMbitious powered by toolcraft

Handelsstraße 1

91166

Georgensgmünd

Germany

Phone: +49 9172 69560

Fax: +49 9172 6956560